Digital consulting and diagnostic capabilities

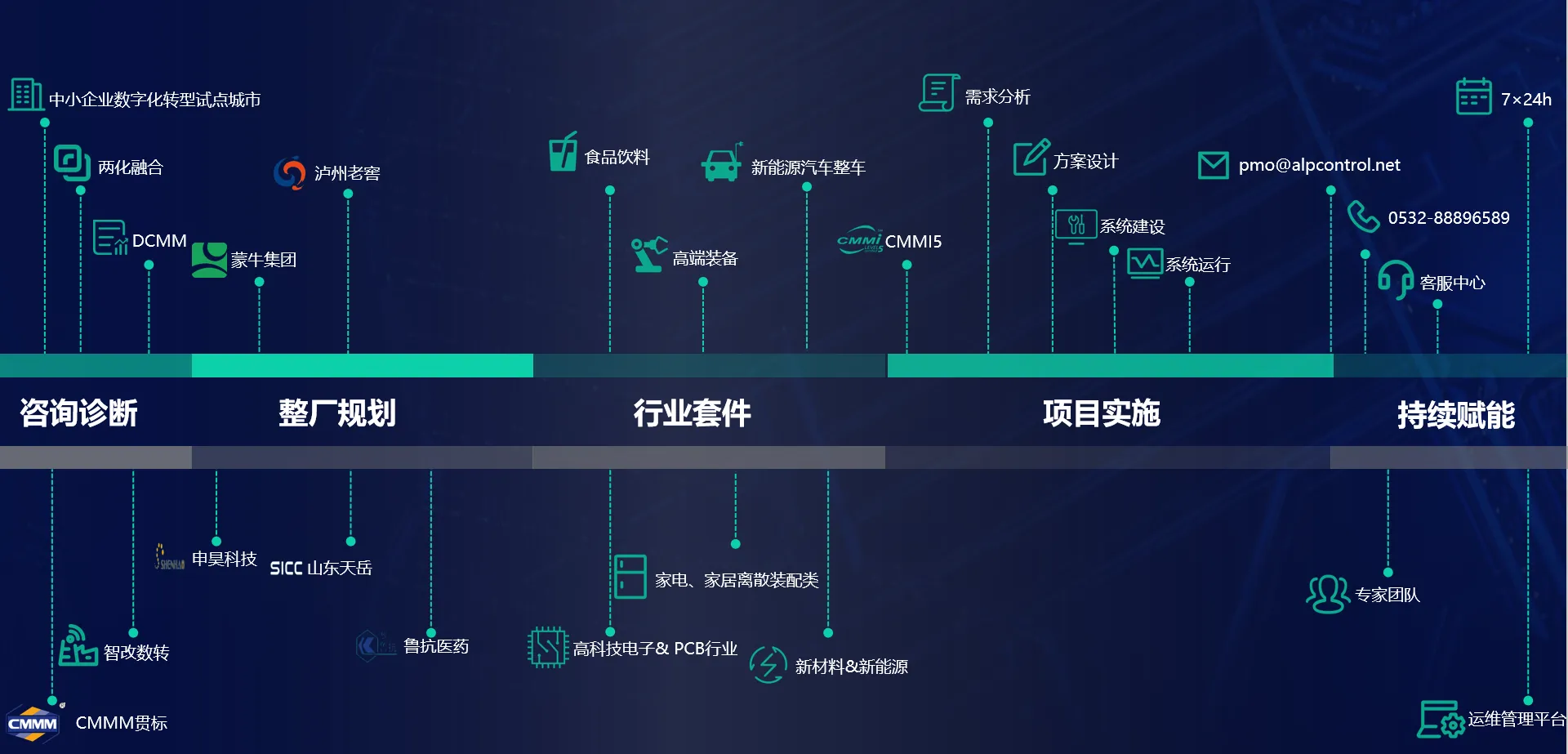

Selected as a CMMM® consulting firm

Consultation and planning services for digital factories and intelligent factories. Services provided to clients such as Hangzhou Shenhao Technology, Lu'an Pharmaceutical, and Shandong Tianyue.

Selected as a key industry digital empowerment center in Qingdao, with the overall assessment ranking first, and formed unique consulting and diagnosis experience.

There are over 3,000 diagnostic service enterprises across the country.

Possessing qualification certificates such as the two-in-one integration management system, intelligent manufacturing CMMM, data management capability DCMM, and the assessment for digital transformation of small and medium-sized enterprises, etc.